Perfume pumps contribute a lot to consumer experience, yet we easily forget about them. The correct pump will make a perfume more pleasurable to use and the wrong one will lead to frustration and dissatisfaction. Perfume pumps have many different specifications such as volume dosage, angle of diffusion, height and type of diffusion. Knowing these different criteria and how they affect the product performance is vital for those who want to create the ultimate client perfumery experience. Also knowing where to buy the right perfume pumps is essential for your perfume brand development.

What types of perfume pumps are available?

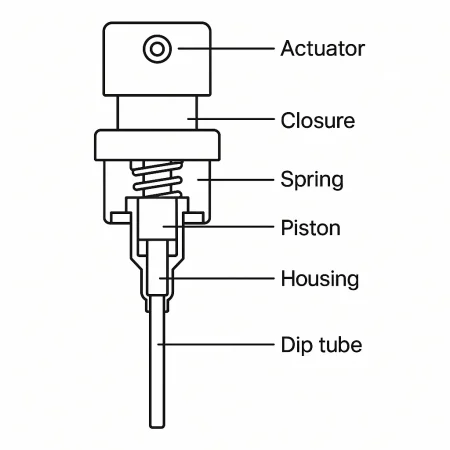

We can make perfume pumps entirely from pp plastic or plastic with an aluminium cover. Most pumps have the following components:

- Dip tube

- Metal spring

- Gasket (to ensure sealing)

- Actuator

- Valve

- Main housing to sit over the bottle neck

- piston

What size of perfume pump is available?

The most common standard size of perfume pumps is 15 FEA which equates to a 15mm bottle neck diameter, in addition you can also find 18 mm and 20 mm diameter pumps. Small neck miniature bottles may sometimes require a pump diameter of around 13 mm.

What is the dosage of a perfume pump?

What do we mean by dosage? This is the amount of perfume which is expelled from the bottle each time that we press on the actuator. Perfume dosage can vary a lot, as mass market pumps from China generally dose about 0.06ml or 0.07ml per spray. Higher quality pumps can be around 0.10 or 0.12ml, while high dosage pumps can be as high as 0.20 ml per spray.

What is the difference between a high profile and a low profile pump?

A high or low profile pump relates to the height of the pump. Some pumps will sit much higher on a bottle and also have a taller actuator. Low profile pumps are shorter, so if you have a short perfume cap a low profile pump is best. This will avoid the cap pressing on the actuator and spraying accidentally. See in the image to the right how one pump is looking taller than the other. There is a wider space between the base part of the pump and the bottom of the actuator on the high profile pump. The bottle neck and perfume bottle size is the same for both bottles, yet one pump is looking taller than the other. In case you didn’t work it out – the one on the left is the normal profile pump. The low profile pump is on the right side.

Why is the diffusion of my perfume pump important?

There are different types of diffusion which affect how people perceive your product when it is sprayed.

1. High quality fine mist sprayers are popular with high quality manufacturers, as they provide a wide, very fine mist on the skin. You can adjust the pump to have a wider or more narrow area of diffusion.

2. A high definition wide cone diffusion pump covers a wider surface, but with bigger droplets than the fine mist sprayer.

3. A short direct spray type has a wider nozzle in the pump and sprays a short jet of perfume. This is more common in mass market lower quality pumps

The spray angle in a perfume point is the angle at which the mist is dispersed when it exits the nozzle. A spray cone of 80 to 100 degrees creates a perfume cloud effect, whereas 60 to 70% is more balanced. Anything under 50 degrees cone we consider to be more concentrated and more targeted. Some high quality suppliers are able to customise the spray angle and the droplet size of their sprayer for the ultimate luxury experience.

What is the normal minimum order quantity for perfume pumps?

This will vary from supplier to supplier. Entirely plastic perfume pumps have a lower minimum order quantity, provided that they are made from regular colours like black or white. Special Pantone plastic colours may require a higher order quantity, though the minimum order quantity will depend on the supplier.

For aluminium coated perfume sprayers standard colour silver and gold perfume pumps generally have a minimum order quantity of 10,000pcs. However, this again depends on the supplier you are working with, as some suppliers will not give less than 30,000pcs per item. If you want a special colour on an aluminium pump, then a minimum order quantity is often 30 to 50,000pcs, but some suppliers will accept less.

Are Chinese pumps lower quality than European and USA pumps?

From the experience of Anisha International, Chinese pumps are still not as high quality as European and USA pumps. They offer a very good alternative at a much cheaper price, but Chinese pumps do not have the same consistency. We work with some very good pump suppliers in China who offer excellent sprayers with fine mist capability. Our partners have excellent quality control and testing facilities for their perfume sprayers. Other factories have not yet overcome the issue of ‘pissing pumps’ which happens when small droplets appear within the spray. Incidentally, we have tested Aptar pumps made in China against Aptar pumps from Europe and the quality of the European pumps was far superior.

Unfortunately, the lead time can be very off-putting when buying pumps from Europe or USA. The lead-times can be eye wateringly long – up to six months to get one shipment. For this reason people may sometimes buy from wholesalers at a higher price instead of directly from the factory, but this approach does not allow you to customise the pumps. Of course, if you are buying through dealers or wholesalers, the price of the pump will be even more expensive. European suppliers are not flexible on custom colours for pumps and have very high minimum order quantities.

How does a perfume pump work

Pressing the actuator of a pump compresses the spring, thus creating pressure that forces liquid up the dip tube. The liquid travels up the dip tube and through the nozzle to be sprayed as a mist. Releasing the actuator expands the spring, creating a vacuum which draws more liquid into the pump chamber through another valve. Another valve at the top of the chamber closes to prevent the liquid flowing back into the bottle after pressing. This is why it is quicker and easier to spray perfume after you have already pressed the actuator a few times. The perfume is already in the pump chamber which makes it quicker and easier to reach the nozzle.

Why do perfume pumps stop working?

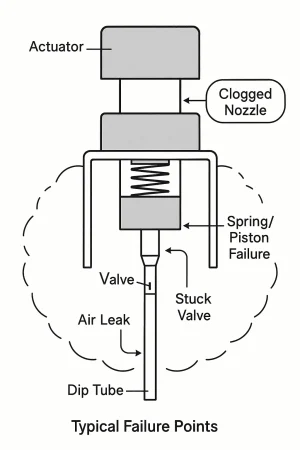

If a perfume pump isn’t crimped tightly enough, air can leak inside and break suction, as even a small leak can stop it functioning.

Most pumps have a metal spring inside which can lose elasticity over time, which stops the actuator from bouncing back.

Sometimes air can get trapped in the dip tube which stops the perfume from drawing liquid.

The spray nozzle of the actuator can sometimes become blocked due to heavy resins in the perfumes settling around it.

As the bottle nears the end of its use and there is little perfume left, it can be difficult to remove the perfume. Sometimes you need to tilt the bottle to allow the perfume to run up the dip tube.

What to do if my perfume pump breaks

Sometimes you may solve a pump problem by removing the actuator and running warm water over it to loosen any heavy residues blocking the eyelet.

However, most pump problems happen due to springs which deteriorate or air blockages, which it is impossible to fix. In this case it is best to just replace the pump.

To replace screw pumps just unscrew it from the bottle and put another screw pump in its place. For crimp pumps and snap on pumps the situation is a little more complex, as the pumps are sealed tight to the bottle. You can try to use a small set of pliers to lift off the metal from an aluminium pump from the neck gently, as too much force will easily break the bottle. Sometimes inserting a small knife under the bottle neck can lift off an aluminium pump.

How to calculate the size of aluminium collar (or cache pompe) you need

Crimp your pump, then take the measurement from the neck of the bottle to the bottom of your actuator. There should not be a gap between the top of the collar and the bottom of the actuator. Equally, the collar should not obstruct the eye of the actuator when you press down, it needs enough space to spray freely. Different suppliers have different specifications and heights of aluminium collar, do not assume that their standard product will fit every glass perfume set you need to use it for.

How can I choose the right perfume pump and collar combination?

- Establish the neck type of the bottle you are using – is it a screw neck or a crimp neck bottle?

- Measure the neck of your perfume bottle using a vernier caliper. If the neck is around 15mm diameter then use a 15mm pump.

- Measure the internal height of your perfume cap. If it is too low, then use a low profile pump to avoid the pump actuator being pressed during transit.

- Ensure that you use a collar which will reach down to the neck of the glass, that there is no gap.

- Check the fitment of the pump and collar with your cap – if the cap is too tight against your collar, then it might remove the collar easily. If this happens you may need to adjust the pp inner of the cap.

- Check the inner part of the cap you are using – does it have vertical grooves or maybe small horizontal ridges? Vertical lines inside the cap are suitable for smooth aluminium collars. Any small ridges or dots in the cap signify that a cap can lock onto the collar. The small ridges in the cap lock onto a deboss or an emboss line in the collar.

- Do you need extra height to be added to your cap? Maybe you can consider a plastic or aluminium step collar which will give extra height.

Often our clients will decide to change the pump they are using at the last minute and ask us to ensure compatibility. However, this is not always as straightforward as it might seem. There are small variances in pump heights and diameters and this can affect how things fit together. If you combine the use of standard caps and bottles, then there are often chances for incompatibility. This is why it is so important to test all the components thoroughly before going ahead to manufacture.

We hope that you have enjoyed this article about the options for perfume pump sprayers. Although this is a very important part of perfume design development, it is often overlooked.

If you enjoyed this article, then you might also enjoy our articles about how to launch a new perfume or how much custom packaging costs. For a full understanding of how to launch a perfume brand please read our complete guide for perfume brands.